Industrial Textiles and Their Applications

Industrial textiles are one exciting field and of of the most popular ones. If you want to know all about it then continue to read.

A specialised branch of technical textile, Industrial textile needs no introduction. If you are thinking about what is industrial textiles, well, it is the textile material that is used in the industry and manufactured industrial products.

Textiles are used widely in electronics, mechanical, chemical and civil industries that use textile materials in direct or indirect ways in finishing, filtration, and industrial or manufactured products.

Some of the examples are silk-screen, roller covers, various types of brushes, fabric circuit boards, computer printer tape, crushing/grinding technology, conveyer and abrasive belt etc.

History of Industrial Textiles

Directly involved with many other industries, Technical textile is a large and growing industry. Although both traditional and industrial textile originated a few thousand years ago, Traditional textile is still considered a little older than industrial textile.

It is with the use of canvas cloth during navigating ships at sea that one can say the journey of modern industrial textile began. With the invention of man-made synthetic fibres, in the first half of the 20th century, this market also underwent a big change.

The uses and demands of industrial textile are increasing as a result of industrialization.

Some Common Features of Industrial Textiles

- Must have high tensile strength.

- Complete capillary function.

- Have good absorption capacity.

- Good heat resistant.

- Push and scratch-resistant.

- One of its characteristics is firmness and long-lasting duration.

- Resistant to bending and expansion.

- Able to withstand high pressure.

- Chemical and odour resistant.

- The fabric should be anti-static and anti-bacterial.

- Provides great flexibility.

Applications of Industrial Textiles

Industrial textiles are defined based on processed raw materials, challenging processes, production strategy and production system. Based on the final application, researchers have classified the industrial textile and the following are the common applications:

Fabric Circuit Board

Fabric Circuit Board was created by two researchers, Qiao Li and Xiao-Ming Tao, from Hong Kong Polytechnic University.

They created it by using “Computerized Knitting Technology in a combination of ancient fabrics and fibrous metal materials. The fabric circuit board holds 3D circuits that are washing resistant, stretching and bending.

Must Read

How to start garment business in India? / भारत में गारमेंट बिज़नेस कैसे शुरू करें

How to start an online Clothing Business? / भारत में ऑनलाइन कपड़ों का बिज़नेस कैसे शुरू करें

Textile Business Ideas

Organic Fiber Brush

The organic fibre brush is mostly made out of horsehair or other organic fibres which makes these bristles naturally soft.

The two main advantages of these brushes are that they are durable, work harmoniously and have a lot of elasticity. These brushes are used to clean sensitive areas where metal brushes cannot be used.

Belt-Drive

This is a fictional drive which is a flexible component of a mechanical system transferring energy from one shaft of the machine to the other. The friction between the belt drive and machine pulley causes the energy.

The use of V-belts is increasing whether it is flat or equal belts. Its efficiency is greater and can transmit the maximum amount of power. They are made of poly-vinyl, vinyl etc.

Decatising Fabric

Also referred to as decasting wrapper, decasting fabric is an industrial fabric employed in decatising machines.

Textile materials are a big part of open decatising and kier decatising machines. These are widely used for the mechanical finishing of woven fabrics. They could be cotton, polyester/ cotton blended, or poly-made blended woven fabrics.

Belt-in-Seat

The first car to use a belt-in-seat was the “range Rover Classic” which has been used in the first seat of the car with standard fitness since 1980.

The seat belt is a three-point harness attached to a shoulder belt and to the seat instead of the car structure.

यह भी ज़रूर पढ़ें

भारत में टेक्सटाइल इंडस्ट्री – सम्पूर्ण जानकारी / Textile Industry in India

Textile Companies in India

How to start a Textile Business in India?

Synthetic Bristle Brush

Made of nylon or polyester or a combination of both, synthetic bristle brushes are used in various ways. The quality of the brushes like durability, firmness etc. is dependent upon various factors depending on the filaments that are used in the making.

For oil or water-based painting, synthetic bristles are used. Some more examples are Lehigh, Eureka, Pinnacle, Nyangle, Logan and more.

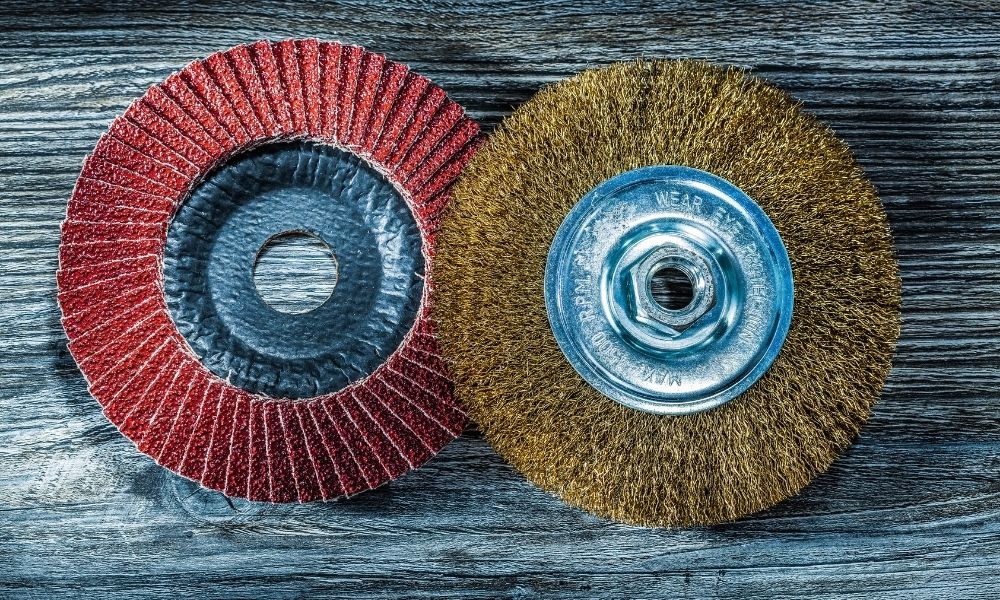

Abrasive Brush

Also known as corrosive brushes, Abrasive brushes are very popular and used for cleaning rust, polishing, removal of oxides, smoothing metals, light corrosion and removal of oxides. They come in different sizes and are made of abrasive grit which is covered with nylon filaments.

The two types of abrasive brushes are cylinder abrasive brushes and power abrasive brushes which are covered with nylon filaments and offer great flexibility.

SoundProofing Parts

Nonwoven textile materials, because of their porous structure, are very popular and widely used for sound absorption applications and sound insulation. They are used as sound diffusers, sound reflectors, noise barriers and sound absorbers.

Physical problems like material thickness & density, fibre diameter, types of fibre, porosity, bonding techniques and air resistance influence the loss of sound energy in textile materials.

Must Read

Perfect Business Ideas for Women

Best Business Ideas in India

Business Ideas in Assam / Bihar / Delhi / Jaipur

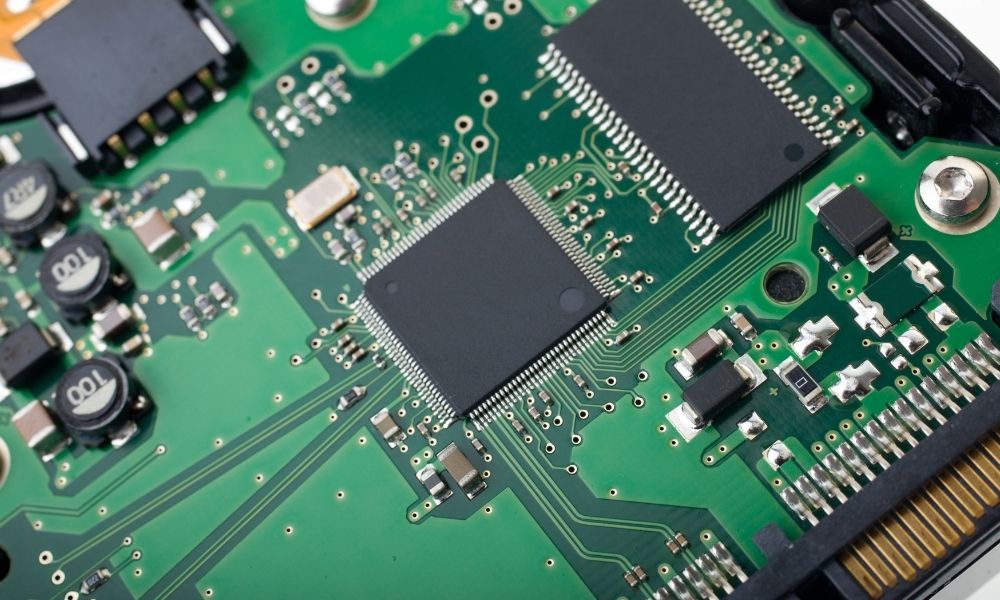

Printed Circuit Board

This is an important part of modern technology. It is based on all modern electronic printed circuit boards and provides electrical mechanical connections for components of different systems.

The main reasons for the growth of the electronic industry are the use of a small portion of glass and plastic fibres.

Fire Hose Flexible Pipe

The raw materials contain cotton, manmade fibre, flax and ramie. Hose pipes are made from textile materials that can bear to stand up to an exact pressure.

These fibres are appropriate for high-pressure delivery and do not leak and the features of these pipes materials are preservative, abrasion in light in weight.

Industrial Brush

Used for finishing various surfaces, household, industrial sector and a few other sectors to clean and smooth the surface of things.

These are mainly used to paint construction sites and to paint buildings or places like yarn brushing, cleaning of driving belts, bottle cleaning, capsule finishing, and textile finishing.

Conveyor Belt

Conveyor belts can be easily installed anywhere and are risk-free. There is a modern-day system that is efficient and the easiest way to transport goods.

Their design makes it easy to move heavyweight from one place to the other regardless of the size.

Maximize Your Online Business Potential for just ₹79/month on Lio. Annual plans start at just ₹799.

How can Lio Help With Starting a Textile Business?

Lio supports you in structuring your consumer and corporate data on your mobile phone so that you can locate the data you need quickly. It’s a simple tally software that aids business owners to arrange their calendars and activities more efficiently and effectively.

It makes data readily accessible for immediate access in accordance with business needs. Entrepreneurs who wish to create a digital marketing business can engage professionals to keep track of these documents, which are necessary so that data can be transferred effortlessly when the time comes.

If you want to start your business in industrial textile then Lio can be of great help. You can manage all your data in this whether it is textile related, clients, customers, contacts, important documents etc.

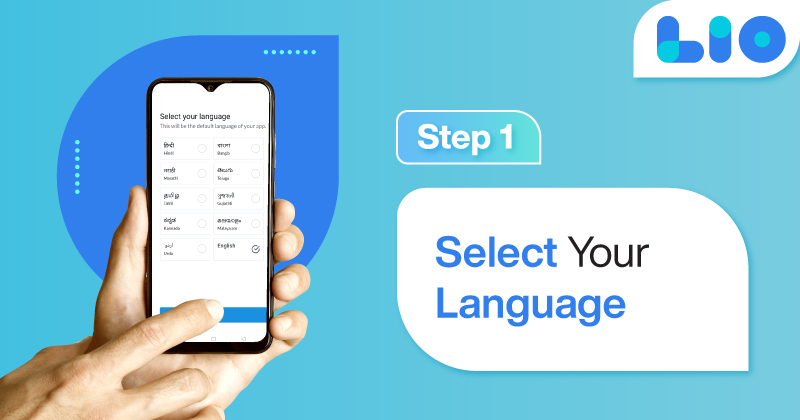

Step 1: Select the Language you want to work on. Lio on Android

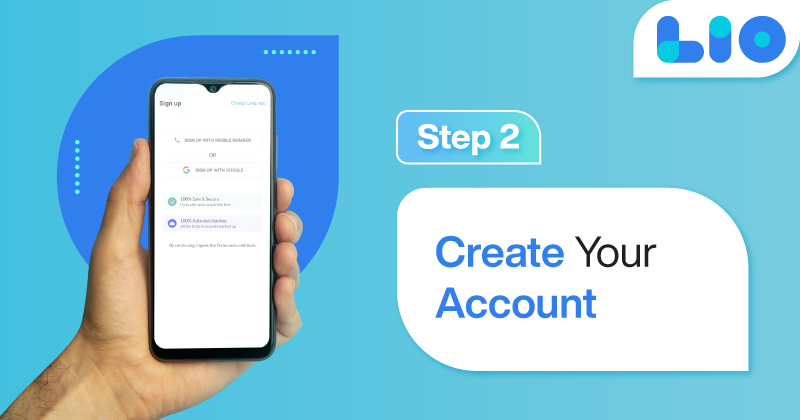

Step 2: Create your account using your Phone Number or Email Id.

Verify the OTP and you are good to go.

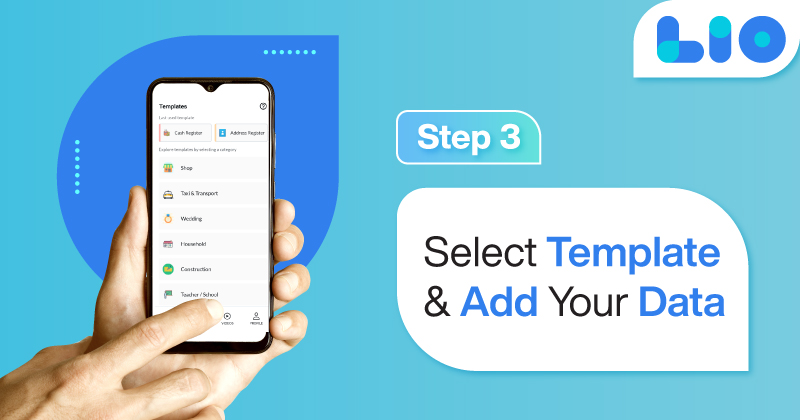

Step 3: Select a template in which you want to add your data.

Add your Data with our Free Cloud Storage.

Step 4: All Done? Share and Collaborate with your contacts.

Conclusion

There are many purposes of Industrial textiles in industrial applications like mechanical, electrical and paint industry.

Frequently Asked Questions (FAQs)

How are textiles used in industries?

Textiles are used in various forms in different industries like agriculture, sporting, construction, medical and hygiene. They are used for conveyor belts, machine clothing, abrasive substrates and filters in industrial manufacturing operations.

Which type of industry is the Textile Industry?

The textile industry is the agro-based industry as it is responsible for converting raw materials into finished products and also have manufacturing, distribution and textile development.

What are some examples of the Textile Industry?

Some of the examples of the textile industries are:

1. Bombay Dyeing and Manufacturing Company Ltd.

2. FabIndia Overseas Pvt. Ltd.

3. Arvind Ltd.

4. Grasim Industries Ltd.

5. Raymond Ltd. and many more.

Name the three segments of the Textile Industry.

The 3 individual segments of the textile industry are – textile product mills, textile mills and apparel manufacturing.

How many types of textiles are there?

Textiles are made of different materials but the four main sources are – plant (flax, bamboo, cotton and jute), synthetic (rayon, polyester, acrylic and nylon), and animal (silk and wool) and mineral (glass fibre and asbestos.

Who is the top importer of Textiles?

The leading importer of textiles all over the world is The European Union with approximately 87 billion US dollars in 2020 in textile imports value.

6 Comments

Thank you sharing for this great post.

Hey Paras,

We are glad that you liked our post. More on the way.

Who is the top exporter of textiles?

Hey Sudha,

China is the top textile exporter of textile globally. It has an approximate value of 154 billion US dollars in 2020.

How can i find out the tensile strength of fabrics? Do those things have tests?

Hello Karthik,

One of the most common methods for evaluating a material’s mechanical qualities is tensile testing. A tensile testing machine, also known as a universal testing machine, is used to conduct tensile tests on various types of machinery.

Prior to tensile testing, the specimen must be properly prepared. Because the tensile testing machine clamps the test specimen, which is often dumbbell-shaped, it should have a thicker cross section near each end. The material is torn apart until it fails during the actual testing, and the load exerted is continuously recorded and captured.