Automation in Manufacturing: Transforming the Future of Industry

Want to know about Automation in Manufacturing? Read the full article to know everything about it and more.

Automation has rapidly transformed the manufacturing industry over the past few decades, as manufacturers look to improve efficiency, productivity, and quality while reducing costs and waste.

Automation technologies such as robotics, artificial intelligence, and the Internet of Things (IoT) have revolutionized manufacturing, leading to new precision, flexibility, and speed levels. In this article, we will explore the role of automation in manufacturing, its benefits and challenges, and the future of this transformative technology.

The Rise of Automation in Manufacturing

Automation has been a growing trend in manufacturing for several decades, driven by the need for greater efficiency, productivity, and quality. In the past, automation was primarily used for repetitive and low-skilled tasks, such as assembly line work. However, technological advancements have made it possible to automate more complex and higher-skilled tasks, such as precision machining and quality control.

Benefits of Automation in Manufacturing

The benefits of automation in manufacturing are numerous and significant. These include:

Improved Efficiency and Productivity

Automation can perform tasks faster, more consistently, and with fewer errors than human workers, leading to increased output and reduced lead times.

Increased Quality

Automation can perform tasks with greater precision and accuracy, leading to higher-quality products and fewer defects.

Reduced Costs

Automation can reduce labor costs, energy costs, and waste, leading to significant cost savings for manufacturers.

Increased Safety

Automation can perform dangerous or hazardous tasks, reducing the risk of injury or illness for human workers.

Greater Flexibility

Automation can be programmed to perform different tasks and processes, enabling manufacturers to quickly adapt to changing market demands.

Challenges of Automation in Manufacturing

While automation offers many benefits, there are also challenges that must be addressed. These include:

High initial Investment Costs

Automation technologies such as robotics and AI can require a significant upfront investment, which can be a barrier for smaller manufacturers.

Skills Gap

As manufacturing becomes more automated, there is a growing need for workers with advanced technical skills such as programming and data analysis.

Job Displacement

As automation replaces certain tasks and roles, there is a risk of job displacement for human workers.

Cybersecurity Risks

As more devices become connected to the internet, there is an increased risk of cyber-attacks and data breaches.

Future of Automation in Manufacturing

The future of automation in manufacturing looks bright, with new advancements in technology and the increasing demand for faster, cheaper, and higher-quality products. Some of the key trends shaping the future of automation in manufacturing include:

Collaborative Robots

Collaborative robots, or cobots, are designed to work alongside human workers, enabling them to perform tasks that are repetitive or dangerous.

Artificial Intelligence

AI is being used in manufacturing to improve decision-making, optimize production processes, and detect defects.

Internet of Things (IoT)

IoT is being used in manufacturing to create connected factories that enable real-time monitoring and control of production processes.

3D Printing

3D printing is being used to create complex and customized parts, reducing lead times and inventory costs.

Maximize Your Online Business Potential for just ₹79/month on Lio. Annual plans start at just ₹799.

How Lio can Help You?

To make your dreams come true of having a business of your own and managing it nicely, Lio App can help you big time. The app lets you keep all sorts of data together in a more organized manner. You can keep records, and create tables and lists while working solo or with a team.

The many features of Lio would help you with your retail business as you would be able to maintain all data on a track that you can use at any time. If you want to upload a document, then you can do that. Know the money transactions, cash inflow, profit and loss you are making, Udhaar, list of products, services, and even the teammates and clients that you have all in one place.

Your retail business ideas will certainly become successful businesses if you go on this journey of managing your business with Lio.

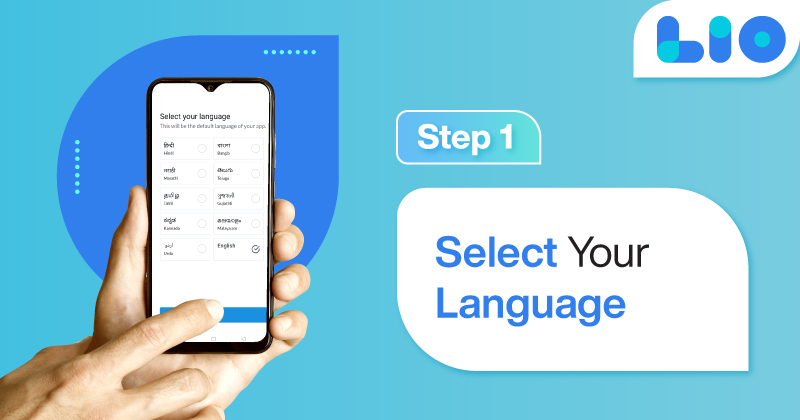

Step 1: Select the Language you want to work on. Lio on Android

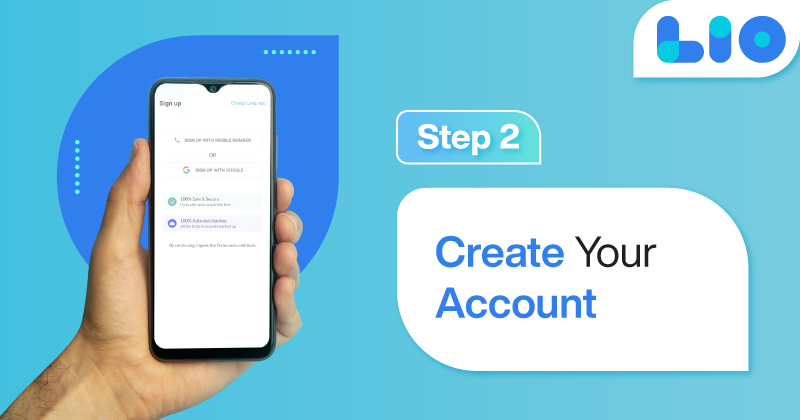

Step 2: Create your account using your Phone Number or Email Id.

Verify the OTP and you are good to go.

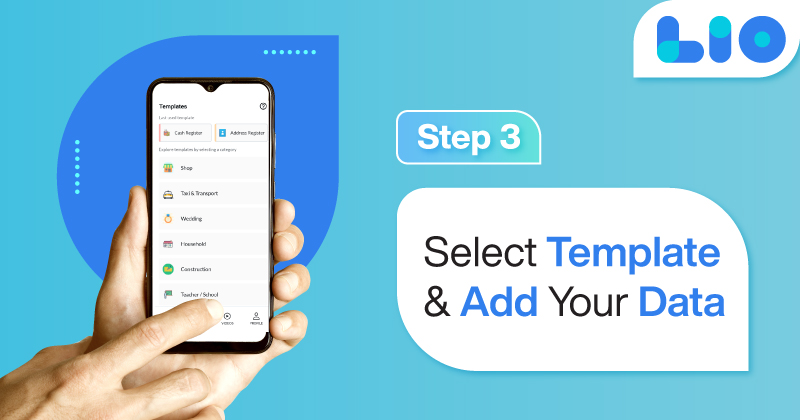

Step 3: Select a template in which you want to add your data.

Add your Data with our Free Cloud Storage.

Step 4: All Done? Share and Collaborate with your contacts.

Conclusion

Automation has transformed the manufacturing industry and will continue to do so in the future. While there are challenges to overcome, the benefits of automation in terms of improved efficiency, productivity, and quality make it a worthwhile investment for many manufacturers. As automation technologies continue to evolve, manufacturers must adapt to stay competitive in a rapidly changing industry.

Frequently Asked Questions (FAQs)

What is the main driver of automation in manufacturing?

The main driver of automation in manufacturing is the need for greater efficiency, productivity, and quality, while reducing costs and waste.

Can automation replace human workers in manufacturing completely?

While automation can streamline processes and increase efficiency, it cannot completely replace human workers. There are certain tasks that require human skills, such as problem-solving, decision-making, and creative thinking. However, automation can allow workers to focus on more complex tasks and improve overall productivity.

How can automation improve safety in manufacturing?

Automation can help improve safety in manufacturing by taking on dangerous or repetitive tasks that may put human workers at risk. For example, robots can perform tasks in hazardous environments, such as welding or handling dangerous chemicals. Additionally, automation can help prevent injuries by using sensors to detect potential safety hazards and shutting down machines when necessary.

What are the potential drawbacks of implementing automation in manufacturing?

One potential drawback of implementing automation in manufacturing is the initial cost of purchasing and installing automated equipment. Additionally, there may be a learning curve for workers to adjust to the new technology and workflow.

Automation may also lead to job loss in certain areas of the manufacturing process, although it can also create new job opportunities in areas such as maintenance and programming. It’s important to carefully consider the potential drawbacks and benefits before implementing automation in manufacturing.