Manufacturing Business Ideas in India for Everyone

Anyone who has landed on this page is most likely looking for manufacturing business ideas. There are lots of opportunities for manufacturing businesses to become vastly successful in India.

Great ideas are what have changed the course of civilization. Every single achievement we have as a species is because of an idea and the willpower of the people behind it to make it happen. Some of these achievements were brought forth by businesses.

For example, the smartphone revolution was started by Apple with the launch of the iPhone.

This article will discuss some of the best manufacturing business ideas for seasoned and aspiring entrepreneurs.

This list has been carefully chosen considering recent trends, government policies, and other socio-economic factors. But first, let us understand the Indian manufacturing landscape a little better.

The Indian Manufacturing Industry Landscape

For over a decade, the Indian economy has focused largely on services rather than manufacturing. This has changed since the launch of the Make in India Campaign, and the tide has shifted in favor of the manufacturing industry.

The goal of the campaign is to transform the country into a global hub for R&D, design, and manufacturing. Huge investments are being made in developing infrastructure, upskilling talent, etc., while also making it easier for businesses to start up and operate.

And ever since the introduction of the Make in India Campaign, the government has been focusing on alleviating a majority of the disadvantages that manufacturers in India were facing previously. Here are they –

- Inconsistent power supply has always been a problem the Indian manufacturing industry has been facing for a long time. Power is not available for 24 hours without interruption in most places.

- Logistics is slow and expensive in India. It generally takes weeks to transport raw materials and finished products to ports and distribution centers.

- Intellectual Property Protection and Enforcement are expensive in India. The government is currently undertaking IP Protection reforms, increasing complexity and reforms.

- Labour productivity is low in India compared to countries like China.

However, on the flip side, there are some advantages enjoyed by the Indian manufacturers. Here are they-

- The Indian commercial law system is based on the British Common Law, which is quite similar to the U.S legal system. Although there are some variations and some regulatory hurdles, the familiar system makes it a lot easier for people from other countries.

- India also has a labor market that is cheaper than even that of China. But manufacturers need to take into account the significantly higher costs of transportation, power, water, etc.

- Speaking of labor, India has a huge talent pool of close to 500 million people, which includes unskilled workers and skilled workers.

- Most Indian factories produce high-quality products because they use high-quality industrial equipment and manufacturing processes borrowed from countries like Japan and the USA.

Small Manufacturing Business Ideas

#1. Coconut Oil Manufacturing

Coconut Oil is a product that is not confined to the walls of a kitchen. It is also used to manufacture oils, hair tonics, cosmetics, and soaps.

A coconut manufacturing business is a great small-scale business that can be started with a relatively small investment. It is also one of the best manufacturing business ideas for rural areas.

There has been a rise in the adoption of coconut oil as more people are becoming aware of its numerous health benefits.

People living in tropical areas where coconuts are abundant can build a solid business out of coconuts. The biggest international market is the US, followed by the Netherlands, France, and Germany.

The basic criteria for starting a coconut manufacturing business are:

- Easy access to raw materials

- At least 1000 SqFt of covered shade and 3000 SqFt of land to carry out operations.

- A project report highlighting the manufacturing technology, machinery requirement, fixed capital investment, and working capital

- Arrange required utilities like water and electricity

The most common machinery required to manufacture coconut oil is Cora cutter, bucket elevator, oil expeller, screw conveyor, filter press, microfilter, baby boiler, filtered oil storage unit, etc.

#2. Handmade/Homemade Biscuits

Here’s an interesting trend these days – people prefer homemade biscuits and ones made by individual bakers over commercially available ones.

This is because homemade ones are of better quality and offer tastes that are different from those of big brands.

Anyone with an interest in baking can start their own small-scale biscuit manufacturing business with minimal capital investment.

It is also an amazing small businesses idea mainly because it requires very little space and a few people to work. Before getting started, it is imperative to understand the market and what people prefer.

For example, if most prospective customers in the immediate market no longer prefer butter cookies, it makes no sense to make them.

A strong marketing plan is also necessary because the competition is stiff in the baking business, and it is a matter of survival to stand apart from the crowd.

The most common raw materials needed are edible colours, flavours, butter, ghee, salt, milk powder, sugar, wheat flour, and yeast.

Bakers will need artillery of equipment too. Some of the main ones are ovens, dough mixer, moulder, oil sprayer, pressure board, spreader, and slab slicer.

#3. Candles And Other Wax Products

The purpose of candles has moved beyond providing light and religious purposes In the present day, they are regarded as an important piece of decoration.

The customer base comprises not just individuals but also businesses like restaurants and cafes. This is a great part-time business for students, homemakers, and those who would like to break the clutter of 9 to 5 jobs.

This business does not demand a lot of space and can be started in a single room as well. Even from a capital perspective, the investment won’t be high.

The market potential for a candle making business can be defined on the basis of:

- Wax used: Paraffin wax, soy wax, palm wax, beeswax, granulated wax, or gel-based wax

- Type of candle: Pillar candle, container candle, votive candle, tea light candle, taper candle, tarts, and gel candles

- Usage of candles: Home decoration, aromatherapy, illumination, etc.

#4. Homemade Chocolates

The chocolate market in India is estimated to be worth $400 million and is growing at a CAGR of 18% per annum. Almost everyone loves chocolates.

Some people even consume dark chocolate daily because of its various health benefits and also try out new flavors and variants.

More and more people are choosing homemade chocolate over those sold by large FMCG companies.

Homemade chocolate is perceived to be healthier, and they are, without a doubt, tastier. The demand for homemade chocolates tends to spike around the festive seasons as chocolates are also a popular choice for gifting.

The main raw materials needed to start this business are:

- Chocolate flavors: For obvious reasons, this is the most important raw material that has to be procured to start a homemade chocolate business. Business owners can choose from a variety of flavors available in the market.

- Colors: Colors are necessary to get customers’ attention. Go for different combinations of colors. Consider going for organic colors instead of synthetic ones.

- Equipment: The basic equipment needed for a homemade chocolate business includes a chocolate mold, forging tools, refrigerators, display case, heating sheets, bowls, etc.

#5. Papad

This is a very popular snack that presents a great business opportunity. Papad is a product that has demand all throughout the year. Starting a papad-making business is simple and requires only a few employees.

A very important part of starting this business is a good recipe. The most popular types of papad include rice papad, ragi papad, kali Mirch papad, garlic papad, sabudana papad, aloo papad, hing papad, and shakuli.

These can be fried, roasted, microwaved, or toasted. Regardless, quality has to be maintained consistently.

The main raw materials required for the business are flour, pulses, flavors, spices, oil, packaging materials, weighing scale, etc.

Homemade papads can be sold to individual buyers, at the local market, or even to department stores in the area.

If business owners would like to serve the international markets as well, they will have to make extra effort to pass all quality checks.

#6. Value-Added Milk Products

India is the largest producer of milk in the world. Almost every state has a dish or a snack whose dominant ingredient is milk or milk products. People, especially city-dwellers, prefer to buy milk and milk products of the best quality.

The demand is high, and the supply is not able to catch up. So, if someone can access fresh milk and knows how to make milk products, the money will keep flowing. The most common products are butter, cheese/paneer, ghee, yoghurt, and cream.

If feasible, business owners can raise their own cattle to get milk, thereby controlling the entire supply chain.

Doing so will also ensure consistency in terms of quality, as milk from the same animals will be used for production on a daily basis.

#7. Incense Sticks/Agarbatti

People burn incense sticks for religious purposes or simply just to spread aroma at their homes.

These sticks also have a wider commercial application at places/events of religious significance. Demand for agarbattis is largely stable, with spikes during festive seasons.

There is also huge demand in the international market. Guess which country has been meeting this demand? India!

The raw materials required to make agarbattis can easily be found in local markets. They are aromatic ingredients, aromatic oils, bamboo sticks, and colored powder.

Getting the right machine is also important. A machine has to be chosen depending on the budget. There are Manually Operated and High-Speed Automatic machines both at different price ranges.

#8. Soda And Flavoured Drinks

India is mostly a warm country and carbonated drinks sold by companies like PepsiCo and The Coca-Cola Company may not be affordable by a lot of people.

So, they turn to soft drinks sold by local players who sell them for prices as low as Rs.5 for a bottle. And these manufacturers are making profits regardless of the low prices.

This is a business that flourishes during summer. It would also be better if manufacturers can sell to stores that are located in high footfall areas.

They can even be sold to places like movie theatres and bowling alleys. Drinks can be made at home using simple ingredients if the volume of supply is small.

Machines can be employed if the scale of operations is bigger as the manufacturing process will be complex without machines.

#9. Readymade Chapati/Paratha

The busy lifestyle of people these days has left them with little to no time to make food like before. And chapatis and parathas take a lot of time to be prepared.

This is why people have turned to pre-cooked/readymade versions of these staple flatbreads. The demand is huge, and it will only grow as time goes on.

This business can be started with minimal investment. There are two types of machines that can help to make chapatis. The first one is semi-automatic and the second one the fully automatic.

The latter takes care of everything from kneading and rolling the dough to making chapatis while the former split the whole process into different parts with some level of human intervention.

#10. Fruit Pulp

The food industry has always had the demand for high-quality fruit pulp to make cakes, ice creams, squashes, etc. With the invention and introduction of new dishes, the demand for fruit pulp such as tomato sauce, jam-jelly, chilli sauce, etc. has only shot up.

The demand is even higher for seasonal fruits such as mango, kiwi, etc because of the longer shelf compared to fresh fruits.

Products can be sold to retail shops or to consumers directly. For a more consistent source of income, manufacturers can build a network of restaurants and cloud kitchens in their area.

Firstly, it is imperative to choose at least a few fruits that have an uninterrupted supply throughout the year – for example, tomato. Choosing the right fruit should also be dependent on the outcome of market research.

To familiarize oneself with the process, it is recommended to visit the manufacturing unit of an already existing business.

#11. Packaged Frozen Fruits And Vegetables

Tons of vegetables and fruits go to waste because of their shelf life. They can be put to actual use by putting them in cold storage.

Apples, strawberries, peas, carrots, etc. are some of the most common fruits and vegetables that are frozen.

Demand for frozen vegetables is growing as they can be made use of right out of the bag. No cleaning or cutting is necessary.

The main markets are cities as people from rural areas and towns already have access to fresh vegetables and fruits.

Manufacturers can demand higher prices for seasonal products during off-season periods. Profits can even be higher if they serve the international market as well.

The main equipment and tools needed for this business include weighing scales, generators, preservatives, etc. The most important equipment of course is the freezer without which nothing else makes sense.

#12. Disposable Plates, Cups, And Cutlery

People are becoming conscious of the negative impacts their lives are having on the environment.

They are hence replacing plastic and other non-biodegradable with bio-degradable alternatives like paper, pulp, bamboo, etc. There is huge profit to be made in the disposable crockery business.

Disposable crockery is used for all sorts of functions like wedding dinners, parties, and get-togethers.

Plates and cups were initially the only disposable crockery items. Fast forward today, it now includes straws, knives, forks, and cups too.

Buyers not only comprise individuals but also corporate customers like event management companies and travel companies.

Manufacturers can even go niche and incorporate designs into these products to command premium prices.

#13. Hand Sanitizer

Along with masks, this is another product whose demand has shot up since COVID-19 took over the world.

Most people possess more than one sanitizer. For example, one for carrying around with themselves, one in the car’s glove compartment, and one for the work desk. People are likely to keep using hand sanitizers long after COVID-19 is gone.

Lots of companies and even local players have introduced their own brand of hand sanitizers. A small-scale hand sanitizer manufacturing business can be started with little investment at home.

All that’s needed are basic raw materials, knowledge of the manufacturing procedure, and bottles. It is one of the best new manufacturing business ideas with medium investment in India.

#14. Concrete Blocks

The boom in construction businesses in India has also brought forth a huge demand for concrete blocks.

People are choosing concrete blocks over the once-popular red bricks because they look better and are more durable. Construction companies prefer them because they are ready-made, helping them complete projects much faster.

These days, concrete blocks are widely used for making garden paths, pavements, flooring, etc. This business can be started with simple machinery and raw materials.

The main raw materials needed are powdered cement, water, gravel, and sand. The business is also known to bring in good profit margins and is one of the best small manufacturing business ideas in India.

#15. Mineral Water

The demand for bottled mineral water is always high because of heavy usage at weddings, parties, and at hotels.

This is a business that will need a lot of attention on the hygiene front. This is one of the reasons why even on a small scale, this business will require more investment than most of the small businesses on this list.

Worry not because the profit margins are also high provided there is a strong marketing and sales strategy as well.

The amount of investment required depends on a few factors like production capacity, location of the plant, transportation cost, type of water used as the source, the type of plant, and its production capacity.

A small plant can be started with an investment of about Rs. 15 Lakhs.

#16. Spices Powder

Indian curries are popular due to the use of exotic spices such as turmeric, coriander powder, red chilli, etc. The problem with large manufacturers is that they all have a generic taste.

On a small scale, spice powder can be a very profitable business idea if business owners can tap into the right audience.

Mix high-quality spices together to create exotic masalas, pack them in pretty containers and charge premium prices. They will sell like hot cakes in no time.

Note: Small businesses should always keep track of their finances, stock levels, employees, and everything in between if they wish to grow into a large business. This level of tracking can easily be done using excel templates like the ones provided by Lio.

Large Manufacturing Business Ideas

Here are some of the best large-scale manufacturing business ideas in India that are poised for growth in the coming years.

#1. Agrochemicals

India is currently the fourth largest manufacturer of Agrochemicals. There is a wide range of products that fall under this segment. Some of them include hormones, fertilizers, pesticides, soil nutrients, insecticides, etc.

There is a huge demand for such products in the domestic market as well as the international market. Agrochemical businesses are highly profitable and lucrative too. However, they demand high investments and strategic planning.

Regardless, there is huge potential for building a strong brand. After seeds, agrochemicals are the major input for farming and cultivating.

Anyone interested in starting an agrochemicals business should firstly select the type of product they would like to specialize in. They can get started with a product that already has acceptance in the market.

If possible, they can even introduce an innovative product and claim a patent for it. The second thing to do is to determine the size of the business.

This will ultimately determine the level of investment in machinery, raw materials, labour, and everything else. The third step is to set up the plant and purchase the required machinery.

In the fourth step, connections have to be built with suppliers to source raw materials. The final step involves hiring people across departments.

This is one industry that is highly regulated by the government and requires different licenses from concerned authorities. This includes licenses for production, marketing, storage, etc. Business registration is also mandatory.

#2. Cement Plant

The country is developing and with development comes infrastructure. Nothing can be built without cement.

India is the world’s second-largest producer of cement and the country’s demand for cement is expected to reach 550-600 Million Tonnes Per Annum (MTPA) by the year 2025.

The biggest driver for this increased demand is the housing sector – accounting for more than half of the total consumption.

Infrastructure, commercial construction, and industrial construction are the other major consumers at 13%, 11%, and 9% respectively.

The industry is set to get a further boost with initiatives such as the development of 98 smart cities. The industry provides employment to more than a million people directly and indirectly.

The following is a brief outline of the steps to set up a cement manufacturing plant –

Step 1: Clarify the cement type and production scale

Firstly, determine the type of cement that will be produced and the volume of production. These decisions have to be made after considering factors like the market size, market demand, cement prices, and investment capacity.

Step 2: Find the right location

The right location makes construction easier, saves on construction costs and subsequent costs. Since cement plants required a vast area of land, they are usually located in rural areas or on the outskirts of urban areas. The plant should ideally be as close as possible to a limestone mine to save on the cost of transportation.

Step 3: Design the factory

Cement factories are large, and their design must be entrusted to a professional designer.

Step 4: Purchase equipment

Many kinds of equipment like thermal equipment, grinding equipment, storage system, dust removal equipment, etc. are needed.

Some large equipment like vertical roller mills, cyclone preheaters, etc. have complex structures and take a long time to procure.

This means they have to be ordered in advance based on the construction schedule to ensure they are installed in the cement factory and operational on time.

Step 5: Factory construction and equipment installation

Once the factory is designed, it is time to get it constructed. The civil engineering and equipment installation should be handled by two different teams.

Step 6: Recruitment and training

Staff should be recruited and trained at least a month before the factory is opened for business.

#3. Rice Mill

Rice is the most important staple food in the country providing food for more than half of the population.

The Indian rice mill market is expected to grow at 3.51% CAGR between 2022 and 2030. People living in rice-producing areas can consider starting this business.

Modern-day mills prevent the mixing of finely broken rice with rice bran and thus making sure the quality of the final product is better.

Given the huge market need both domestically and internationally, a rice mill is a very profitable business. To cater to the international market, rice mills have to ensure high-quality standards.

The main machinery required to start a rice mill includes cleaning machines, de-stoning machines, de-husking machines, paddy separators, rice whitening machines, polishing machines, and grading machines.

A rice mill can be started with about 1000 sqft area of land. Business owners should also make sure that the proposed land for the factory is close to suppliers of raw material i.e., paddy.

To start operations, new rice mills have to be registered appropriately. It has to be registered as a business. A factory license is also necessary along with a No Pollution Certificate.

#4. Tea Business

Indians love a good cup of Chai no matter what time of the day it is – it acts as an energy booster. Indian tea has also amassed a huge following in the international market.

A tea garden with a processing unit can turn out to be a very lucrative business. The Nilgiris, Assam, and Darjeeling are the main tea-growing regions of the country. The market demand is huge both at the national and international levels.

Withering is the first step in the tea manufacturing business. It is the process in which leaves are plucked and dried to reduce moisture content.

The moisture content of the leaves should be reduced to 50-70% from the original of around 80%. The second step involves Sifting, which is the removal of any waste materials like sand, gravel, dust, and small stones. Conditioning is the third step where the leaves are shredded using a leaf shredder and rotor vane.

The fourth step is called Maceration and it is the process where leaves are sent for rolling. There are two ways of doing this.

The traditional process, where the leaves are passed through the roller and broken down into small pieces. The CTC tea processing method is the process where the machine does all the crushing, breaking, and rolling.

This method saves a lot of time and energy. The leaves become ready for oxidation after maceration. After oxidation, the next step is drying.

The leaves are put into dryers to bring down the temperature to 3%. The last step is called sorting. Tea is usually sold in three sizes i.e., whole lead, broken, fanning, and dust with their sizes ranging from 2cm to 0.5 mm. After this is done, it is packed and sent for distribution.

Related: Business Ideas For People In Kerala

#5. Textile Mill

The Indian textile industry exports to countries all over the world including the USA. This is a very traditional sector that uses modern machinery and techniques.

The government has also come forward in support of the industry with a number of favorable export promotion policies. Huge amounts of money can be made in the business.

Textile mills provide raw materials to make apparel and textile products. They do so by transforming natural and synthetic materials into fibre, yarn, and thread. Fabric is made by knitting and weaving.

Here are some things that should be kept in mind before starting a textile mill:

- The factory must be strategically located so that it is in an area that is well connected for logistics purposes and also does not face any water and electricity-related issues

- It should be close to sources of raw materials

- There is enough storage space that is well ventilated because textiles tend to leave behind toxic fumes and dust

Along with registering the company, textile mills have to get the following additional licenses.

- Pollution License from the State Pollution Control Board

- Factory License to register the premises with the local authority in charge of implementing a safety and health management system on the premises and also of risk management.

#6 Wine Production

A majority of the country’s wine is consumed in cities like New Delhi, Mumbai, Kolkata, Bangalore, and Pune.

The demand is increasing at a steady pace in other cities as well. Wines can be classified according to carbon dioxide content, sugar content, and other factors. The Indian wine market is estimated to be worth $150 Million and is growing at a CAGR of 20-25%.

Though it takes a substantial amount of investment, the payoff is huge. For example, the investment needed to make fine wine (from grapes) varies from Rs.4 Crores to Rs. 7.5 Crores per 100,000 litres including land, plant, machinery, building, and working capital expenses.

This excludes marketing costs. Investment for cheaper ‘fortified wines’ will cost roughly half of the above amount.

The following are some of the key regulations related to wine production in India that prospective business owners should be aware of.

- License to manufacture wine in India: The Constitution has given the power to the State Governments to levy or collect duties of excise and draft rules on import, purchase, sale, or manufacturing of alcoholic liquor including wine.

- FSSAI Registration: Any company involved in importing, bottling, and marketing wine in India is required to obtain a license under the FSSAI Act of 2006.

- Bureau of Indian Standards: After an application is submitted, a preliminary factory evaluation is carried out by authorities. Samples are then taken and drawn for independent testing. A BIS certificate is provided if the sample is acceptable.

- Sample and Quality Check Regulations: The sample of any imported wine will be sent by the authorized officer for analysis.

#7. Toughened Glass Manufacturing

As the name suggests, toughened glass is a glass that is treated to make it able to withstand pressure and not shatter as easily.

The demand for toughened glass is climbing quickly, driven mostly by commercial and domestic construction sectors.

The other consumers of toughened glass include the automobile industry, railways, and manufacturers of ships. Considering everything, this is one of the best B2B manufacturing business ideas in India that entrepreneurs can consider.

Maximize Your Online Business Potential for just ₹79/month on Lio. Annual plans start at just ₹799.

How Lio Automation Can Help You Business Process

Business automation is used by not just big businesses but all entrepreneurs and start-ups. It is something that has really helped companies run a smoother process and learn from their mistakes. Companies who have adopted automation have really made a mark and have from 10X faster with the best possible results.

Lio Automation gives you many amazing features that make your work super simple and effective. There are very many features that will help you and your business in various aspects. From connecting and staying in touch with your customers, to working together as a team, and everything in between, Lio Automation will truly make your business run smoothly and make it reach new heights of success.

If you are using Lio Automation for your business processes consider all your data safe and secure all the time. Not only is the data saved in the cloud, but it also offers a data versioning feature in which you can actually see the many changes the document or file has gone through and who has made those changes. You can save the version of the file as required by you.

Another great feature that Lio Automation offers is colour formatting the sheet. Colour formatting can help bring information and more clarity to the audience. Applying colours to different parts of any data will let you narrate a more effective story that easily catches one’s attention as well.

You can create dashboards for each file which would give you the clear details of your company’s operations, marketing campaigns, sales and other analytics. This is a one useful feature that would truly make a difference to your business and help your see all the processes clearly so that you can make well-informed decisions.

Since customers are a big part of any business and staying in touch with them is a crucial job, Lio automation gives you the ability to automate Whatsapp communications. Automating WhatsApp communication is another popular trend that businesses can benefit from. With the help of this, you would be able to save a lot of time, boost your customer retentions and renewals, save a lot of money, have lower operating costs and much more.

Lio Automation also makes working in teams very easy with their Task feature. you can not just assign tasks to your team efficiently. You can set the priority of each task along with the due date. Your team will get a notification about the task automatically, even on Whatsapp, they can see their assigned tasks in the app, mark them complete, and you will get a notification on Whatsapp!

Not just this, Team management and work allocation are made super easy with Lio Automation. You can also work with teams in real-time and see all the changes happening.

You can share invoices and receipts with your customers while also sharing the payment links with them to make the whole transaction process smoother and absolutely hassle-free for everyone.

Lio also makes collecting valuable reviews from customers very easy with its automation process. Along with this, you can also manage leads very easily with the help of automation. Now no lead would be missed and can be responded to the minute you receive them.

There are several other amazing Lio automation features that are made so that you and your business can benefit from them. Excited to know more about it? Start with your Lio automation process for your brand and start your journey to success.

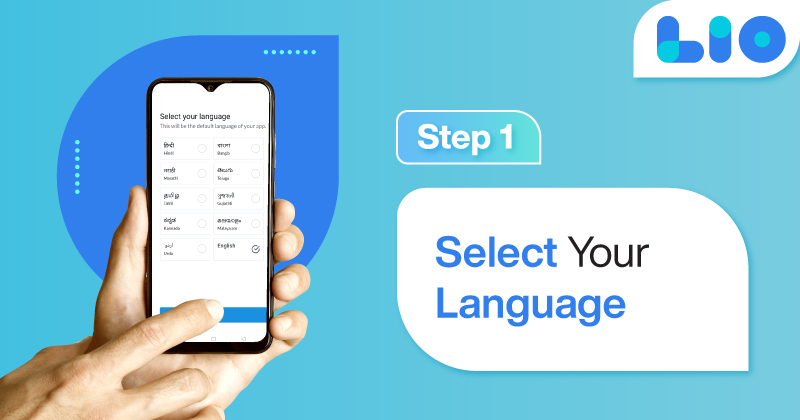

Step 1: Select the Language you want to work on. Lio on Android

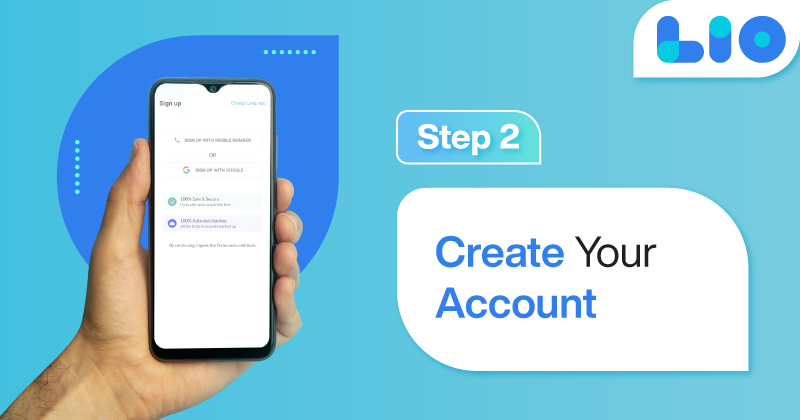

Step 2: Create your account using your Phone Number or Email Id.

Verify the OTP and you are good to go.

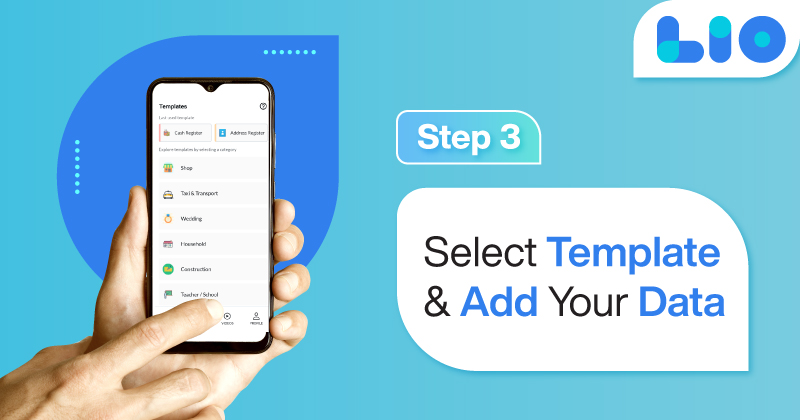

Step 3: Select a template in which you want to add your data.

Add your Data with our Free Cloud Storage.

Step 4: All Done? Share and Collaborate with your contacts.

Conclusion

The Indian economy has opened up a lot in terms of business opportunities and ease of doing business for both small and large manufacturing businesses.

With people having more disposable income, demand is also on the rise. The time has never been more right for entrepreneurs to start their journeys.

I hope you find this article helpful.

6 Comments

Very well written. Good work.

Hey Nitin,

Thank you so much for your feedback.

Textile mill section and and its video was very helpful. Amazing blog.

Hello Sheerja,

Thank you so much for your warm words.

I’m very delighted this topic piqued your curiosity.

Please let me know where I may buy disposable plates and cups in India in large quantities.

Hello Keshav,

Numerous websites, including Amazon, Flipkart, IndiaMart, TradeIndia, BigBasket, and others, sell disposable plates and cups in bulk.

Please do your research and make a decision based on your needs.