Create Effective Manufacturing Work Instructions | Guide

Gaurav Singh Rawat

- May 28, 2024

- 7 Min Read

Manufacturing work instructions are essential documents that guide workers to perform tasks accurately, efficiently, and safely. They provide step-by-step procedures for building, assembling, packaging, and shipping products that meet required specifications.

In this comprehensive guide, we’ll explore the importance of manufacturing work instructions, their key components, and best practices for creating and implementing them effectively.

What are Manufacturing Work Instructions?

Manufacturing work instructions are detailed, step-by-step guides that outline the best way to complete specific tasks within a manufacturing process. They serve as a reference for workers, ensuring consistency and quality in the production process. Manufacturing work instructions can be presented in various formats, such as written documents, visual aids, or digital guides.

Manufacturing work instructions play a crucial role in standardizing processes, reducing errors, and improving overall efficiency on the production floor. They also help in training new employees and maintaining a safe working environment by incorporating safety guidelines and precautions.

Benefits of Manufacturing Work Instructions

Implementing clear and effective manufacturing work instructions offers several benefits to organizations:

Increased Productivity and Efficiency

Manufacturing work instructions help standardize processes, ensuring tasks are completed consistently by all workers. This leads to increased productivity, reduced costs, and improved efficiency.

Improved Quality and Reduced Errors

By providing clear, step-by-step guidelines, work instructions help reduce errors and defects in the manufacturing process. This results in higher quality products that meet customer expectations.

Streamline Work Instructions

Simplify your manufacturing processes with clear, effective work instructions. Improve efficiency and reduce errors today!

Enhanced Training and Onboarding

Work instructions serve as valuable training tools for new employees, helping them understand processes quickly and reducing the time required for onboarding. They also facilitate cross-training and upskilling of existing workers.

Ensured Safety and Compliance

Incorporating safety guidelines and precautions into work instructions helps create a safer work environment and reduces the risk of accidents. They also help ensure compliance with industry standards and regulations.

Preserved Institutional Knowledge

Documenting best practices and expert knowledge in work instructions helps preserve valuable know-how within the organization, even as experienced employees change roles or leave the company.

Scalability and Flexibility

Standardized work instructions allow companies to scale production output and operations rapidly. They also enable flexibility to accommodate process changes and improvements without causing significant disruptions.

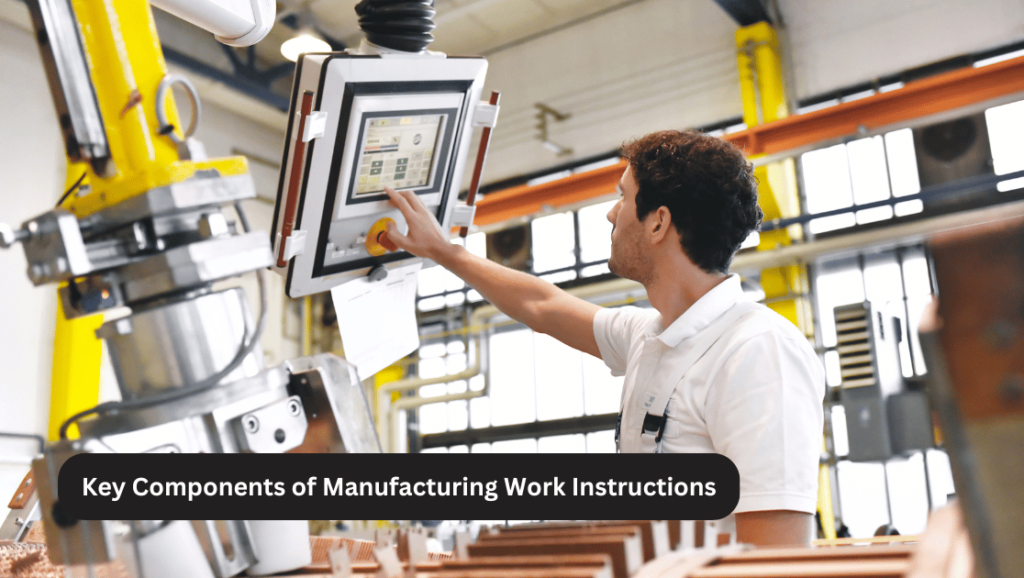

Key Components of Manufacturing Work Instructions

The key components that should be included in effective manufacturing work instructions are:

Clear Objectives and Scope

The work instructions should clearly state the purpose of the task and define the extent and limits of the instructions. This helps provide context and sets expectations for the worker.

Sequential Steps and Detailed Procedures

Break down the manufacturing process into detailed, step-by-step procedures in the order they need to be executed. Each step should be concise yet comprehensive, including all necessary sub-tasks and quality checkpoints.

Optimize Production Steps

Enhance your manufacturing workflow with detailed work instructions. Ensure consistency and quality across all operations.

Required Materials, Tools, and Equipment

List all the materials, tools, and equipment needed to complete the task. Consider adding this information at the beginning so workers can gather everything before starting.

Safety Precautions and Guidelines

Incorporate all relevant safety measures, required personal protective equipment (PPE), and potential hazards associated with the task. Following safety protocols is vital to prevent accidents and ensure employee well-being.

Visual Aids and Multimedia

Include pictures, diagrams, flowcharts, tables or even videos to illustrate complex steps and improve comprehension. The right balance of text and visuals is key – they should complement each other but also be able to stand alone.

Quality Control and Expected Results

Explain how each step contributes to product quality and define clear standards for the finished output. Identify critical points where quality checks should be performed.

Troubleshooting and Problem Solving

Provide guidance on common issues that may arise during the process and how to resolve them. Include contingency plans for potential disruptions or deviations.

Best Practices for Creating Manufacturing Work Instructions

The key components that should be included in effective manufacturing work instructions are:

Engage with Employees for Practical Insights

When developing manufacturing work instructions, it’s crucial to involve the employees who perform the tasks daily. Their hands-on experience provides valuable insights into the practical aspects of the work, potential challenges, and opportunities for improvement.

Conduct interviews or group discussions to gather their feedback and suggestions on existing manufacturing work instructions. Encourage them to identify gaps or areas that require clarification. By engaging with employees, you can create manufacturing work instructions that are more accurate, user-friendly, and effective.

Enhance Workforce Training

Provide your team with comprehensive work instructions. Improve training, reduce mistakes, and increase overall efficiency.

Write Clear, Concise, and Accurate Instructions

Manufacturing work instructions should be written in simple, easy-to-understand language. Avoid using jargon or ambiguous terms. Be concise while still providing all necessary details.

Break down complex procedures into clear, sequential steps. Include every detail, no matter how small or seemingly obvious. Explain the purpose and significance of each task to provide context. Clear and accurate manufacturing work instructions reduce errors and ensure consistency in the production process.

Incorporate Visual Aids and Multimedia

Visual elements such as pictures, diagrams, flowcharts, tables, and videos can greatly enhance the effectiveness of manufacturing work instructions. The right balance of text and visuals is key to improving comprehension and clarity.

Use visuals to complement the written instructions, but ensure they can also stand alone if needed. Consider using 3D models or process maps to give workers a clear understanding of the manufacturing process. Interactive elements can provide additional information on sub-processes when required.

Focus on Standardization and Consistency

Establishing standardized processes is a fundamental principle of creating effective manufacturing work instructions. By documenting the single best way to perform each task, you reduce errors, improve quality, and simplify training.

Ensure that manufacturing work instructions are detailed enough to produce consistent results across different workers and shifts. Regularly review and update the instructions to maintain standardization as processes evolve and improvements are made.

Prioritize Safety and Compliance

Manufacturing work instructions must prioritize safety and compliance with industry regulations. Clearly outline all safety procedures, required personal protective equipment (PPE), and potential hazards associated with each task.

Incorporate relevant safety guidelines and precautions directly into the manufacturing work instructions. Specify how to properly use protective equipment and reference any applicable industry standards or regulations.

Conclusion

Manufacturing work instructions are vital tools for ensuring consistency, quality, efficiency, and safety in manufacturing processes. By following best practices for creating and implementing manufacturing work instructions, organizations can improve productivity, reduce errors, and foster a culture of continuous improvement.

As the manufacturing industry evolves, the importance of clear and effective manufacturing work instructions will only continue to grow. Embracing digital solutions and leveraging technology can further enhance the accessibility and effectiveness of manufacturing work instructions, enabling organizations to stay competitive in an ever-changing landscape.

Frequently Asked Questions (FAQs)

What are the different types of manufacturing work instructions?

Manufacturing work instructions can be presented in various formats, such as written procedures, visual aids, interactive digital guides, and more.

How often should manufacturing work instructions be reviewed and updated?

Manufacturing work instructions should be reviewed and updated periodically, typically annually or whenever significant process changes occur.

Who is responsible for creating manufacturing work instructions?

Creating manufacturing work instructions is a collaborative effort involving experienced workers, engineers, subject matter experts, and other relevant stakeholders.

How can manufacturing work instructions improve safety in the workplace?

Manufacturing work instructions improve safety by incorporating safety guidelines, required PPE, and precautions, and by standardizing processes to reduce the risk of accidents.

What role do manufacturing work instructions play in continuous improvement?

Manufacturing work instructions support continuous improvement by facilitating the identification of process inefficiencies and opportunities for optimization.